The race is on in the increasingly crowded cell-based meat space to provide an affordable, industrially scalable production method, but cultured meat production now relies on the use of expensive Fetal Bovine Serum (FBS) as the culture media. Also, FBS is derived from blood collected from the calves of pregnant dairy cows at slaughter, but eliminating animal cruelty is a key tenet of cell-based meat production.

Dutch startup Meatable has developed a feasible solution to these problems using a cell-programming technology called OPTi-OX developed in 2014, which, in turn, was based on Nobel Prize-winning research that showed that mature cells can be reprogrammed to become a more powerful type of stem cells, called pluripotent cells.

Meatable attracted $47m Series A funding in March 2021 for its pioneering technology becoming yet another benefactor of the growing investments in the cell-based meat market reflecting investor, industry and consumer interest in achieving cruelty-free scalability.

In December 2020, the scientific journal Nature stated that “for commercial viability, the industry will need to find ways to produce tissue at a massive and unprecedented scale." Meatable’s use of pluripotent cells offers a solution as, unlike stem cells used in cellular meat production, which can only divide between 40 and 60 times, pluripotent cells are able to divide limitlessly.

The Series A round, which brings Meatable’s total funding to $60m, involved a number of heavyweights in the biotech investment scene, including Dutch biotech DSM’s investment arm DSM Ventures and a former executive director of the Bill & Melinda Gates Foundation.

Other cell-based meat producers have also said they will use plant-based substitutes for FBS, including Eat Just, whose GOOD Meat Cultured Chicken recently debuted in a Singapore restaurant. Another Dutch cultured meat startup, Mosa, which produced the world's first cell-based burger back in 2013, has also ditched FBS but has not revealed its new production technology.

Meat cuts in three weeks

The research that spurred the development of OPTi-OX technology was led by university researchers Roger Pedersenat at Stanford and Mark Kotter at Cambridge. In 2014, they succeeded in manipulating pluripotent cells and dictating their growth, though their objective was for neurological application. Kotter, who continues stem cell research for human health benefits under his startup bit.bio, patented the technology.

Former McKinsey consultant Krijn De Nood and cellular meat researcher and advocate Daan Luining, who had met Kotter through his work with cellular agriculture enablers New Harvest and the Cultured Meat Foundation, were sold on the OPTi-OX technology and Meatable was born in February 2018.

OPTi-OX which stands for OPTimised inducible OvereXpression leverages Kotter's ability to build specific transcription factors, or proteins that help to program genes by binding to nearby DNA, into the DNA of pluripotent cells. This was a first, in effect creating “blank slate” cells with an exceptional capacity for malleability. When Kotter met cellular agriculture expert Luining in 2016, he had no prior knowledge of cell-based meat but was rapidly convinced by Luining of the suitability of his technology to cell-based meat.

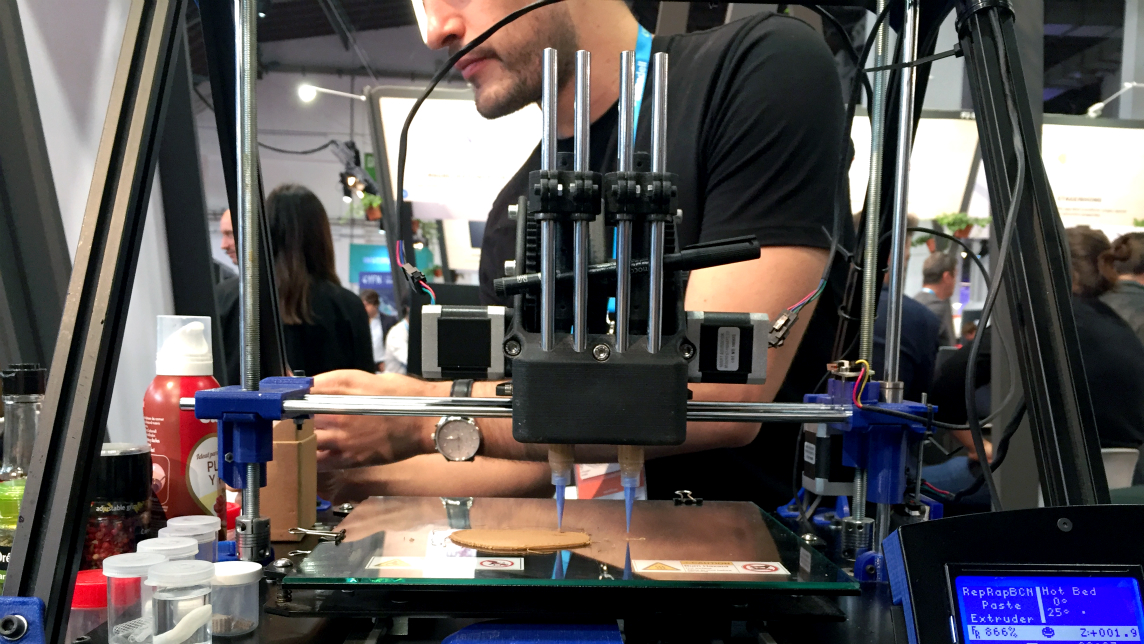

Meatable began in 2018 by using pigs' pluripotent cells to replicate the natural process of fat and muscle growth and produce large batches of cells in a bioreactor in days and in proportions that emulated traditional cuts of meat in just three weeks. Last year the startup created its first pork sausage.

Besides dividing up to 2.5 times as fast as other stem cells, pluripotent stem cells can also be transformed into whatever type of cell the scientist chooses. This contrasts with, for example, muscle stem cells that can only ever proliferate to create muscle. Additionally, only one pluripotent cell is needed to start the reproductive process.

A major advantage of OPTi-OX over other cellular culture techniques is that by using pluripotent stem cells, muscle and fat cells have a similar origin and can be cultivated together. This is unlike what has been achieved to date as adult muscle and fat stem cells need to be mixed after culture, a difficult process for most cell-based meat startups. Also, unlike FBS, pluripotent cells can be sourced continually and painlessly from the blood inside the umbilical cord of a newly-born animal.

Game-changing technology

Meatable’s technology is adaptable to any cell-based species. It aims to produce beef next as it is the most environmentally unfriendly and resource-intensive meat. It is planning a pilot next year with commercialization not expected to happen before 2025, something that does not worry the startup.

“We’re not necessarily going for first; we’re going for best,” Luining told media.“We have seen the nugget and the chicken burger, but we’re working on whole muscle tissue,” he said separately.

The $47m Series A investment will be used for a production facility at the company's base at the city of Delft's Biotech Campus to propel its pork pilot, to begin work on cultured beef and grow its team from the current 35.

Four new investors joined the Series A lineup. These are DSM Venturing, angel investors Rick Klausner, former executive director of the Bill & Melinda Gates Foundation and founder of three medical biotechs and Jeffrey Leiden, the executive chairman of Vertex Pharmaceuticals and former director of the US National Cancer Institute, and biotech VC Section 32, founded by serial investor and founder of Google Ventures Bill Marris.

“We see a smart start-up that has accomplished a lot in a short amount of time,” Klausner said. “They have a great team and game-changing technology that can address the challenges around the global food insecurity issues our planet is facing. They have all the right ingredients to become the leading choice for sustainably and efficiently produced meat.”

DSM Venturing’s advisor Osborne Clarke said: “Meatable’s proprietary platform technology enables a fundamentally more cost-effective and scalable production process. It replicates the natural process of fat and muscle growth, in proportions that emulate traditional cuts of meat. The entire process, when fully developed, is expected to take only weeks to produce meat.”

The returning investors were alternative protein foodtech investor Agronomics, TransferWise founder and prolific investor Taavet Hinrikus, and BlueYard Capital and Humboldt, both US investors with a biotech interest. The European Commission had previously invested in Meatable’s $10m seed round via its Eurostars R&D program.