Years after 3D printed food and cell-based meat entered the public consciousness with promises of future food security and sustainability, their large-scale production continues to be challenging but Spanish startup Cocuus aims to make industrial-scale cell-based food a reality.

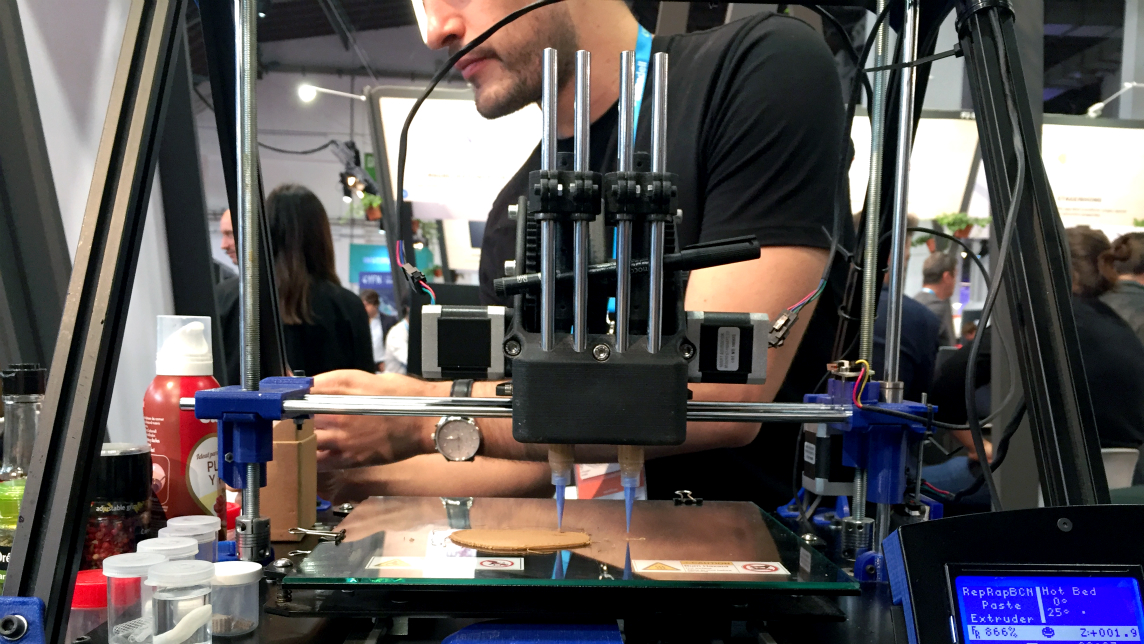

Founded in 2017, Cocuus launched its first two pioneering products in 2018. They are: LASERGLOW, a laser printer and design tool for food, and LEVEL-UP, a culinary inkjet printer. It has since turned its attention to developing technology for industrial-scale 3D printing of cell-based food and is also innovating a 3D printer for purees for people who are unable to eat solid food, with production planned within the next two years.

Co-founded by serial multisector entrepreneur and electronics expert Patxi Larumbe and industrial designer Daniel Rico Aldaz, Cocuus has won foodtech sector accolades including Ingenia Startup Award in 2020 from the Spanish Association of Food and Beverages, HIP Prize in 2019 for innovation in the Spanish hotel and catering sector and Most Innovative Company at FoodTech Barcelona in 2018. It has also gained top clients for its food printing design tools, including Michelin Star chefs such as Ferran Adriá.

With only a modest investment of €1.5m to date, including personal savings, bank loans and some local innovation funds, the startup is now planning a €2m funding round in the third quarter of this year, when it hopes to secure agro-industry investment.

CompassList interviewed Larumbe, Cocuus' Chief Communications Officer after the recent New Food Invest conference, at which it was invited to pitch.

This interview has been translated from Spanish and edited for length and clarity.

As entrepreneurs with multiple non-foodtech-based startups under your belt, why choose foodtech and innovating with printed food?

Seven years ago, when 3D printers began to flourish in Spain because of the expiry of worldwide patent rights in place since the 1980s, we [Larumbe and Rico] had already been working with the sector for 20 years. This included having directed a department in which spare parts for 3D printers in the UK and US were designed. When the patent was freed up, we decided not to follow the standard route of plastic 3D printing and decided to design printers for food production because we saw less competition in that area.

We had already been experimenting for 3–4 years in our garage lab in our free time. We saw that food design was becoming very popular, especially with the advent of people taking photos of their food and sharing them on social media. So we thought food design and branding would be very valuable for food producers and hospitality companies to better promote their products and we began innovating in this area. We left our jobs to work on this full-time in 2017 because we won entry to an accelerator in our region, Navarre, called Orizont. That meant we were obliged to found a company, so Cocuus, meaning “cook” in Latin, was born.

You had already developed and patented your first product, LASERGLOW, before founding the company. How is it unique?

Firstly, given the knowledge we had of the 3D printing sector and the tech, we decided to work with a laser instead of a plastic extruder, which was a first. LASERGLOW is both a 2D and 3D laser food design tool and printer – a machine that changes the morphology of the food and can carve, mold and brand food, making 3D impressions using viscous food such as biscuit mixture or pastry. You can use the laser on all kinds of solid food, including meat, fish or vegetables. It's designed to surprise and impress diners, as you can really recreate any design including photographic images. LASERGLOW also has a changeable head so that you can remove the laser and put in an extruderto print viscous foods.

What we have over our competition is speed, moving at up to 200mm/sec depending on the material. This is precisely by using a laser instead of a nozzle, which other brands use. The laser basically creates objects by sculpting any solid foodstuff inserted, instead of adding to it as an extruder does.

Typically, food printers take 30 seconds to print one layer and may use 30 layers to produce a design in chocolate. LASERGLOW takes 30 seconds to print what normally takes 15 minutes.

What we have over our competition is speed, moving at up to 200mm/sec

This is a first and we are the owners of the patent. We know that the technology had to be very easy to use in kitchens by non-technological people so the designs just have to be copied and pasted on a computer and sent to the LASERGLOW printer just like with a normal printer. Anyone with zero prior experience can use it to make amazing designs.

We commercialized it in mid-2018 in three sizes, with prices from €8,000 to €18,000 – the bigger the machine the more powerful and faster. It is aimed at chefs, catering companies, hotels, restaurants, theme parks, cruises – basically companies that want to surprise their customers. A catering company making thousands of canapés will need the largest model.

The branding possibility is the main function of your second product LEVEL-UP? What is different about it?

We had realized early on that it would be commercially interesting to have a technology that would give color to food designs because lots of people were asking for it, especially for printing their logo. Our LASERGLOW tech could produce the Coca-Cola logo but we couldn't make it red. So we investigated the world of inkjet and modified the existing technology to enable us to use food colorings. Thus, ours was one of the first printers using inkjet colors. LEVEL-UP works like an inkjet printer. The laser moves closer to the object that is inserted inside the printer, guided by a sensor.

The main difference is that this product is exclusively for 2D designs such as logos and can even print on liquids with froth such as beer and coffee in a glass or cup. The product took one and a half years to design and was commercialized at the end of 2018. It is tailor-made for today's Instagram society, as companies can literally put their logos on their food or drinks and market themselves in a unique and memorable way.

LEVEL-UP has a catalog of designs to choose from and also allows customers to send designs directly to print via their mobile. These can include photographs, for example, that can be used for a special birthday celebration, or even whole chunks of written text, as the bio-ink we use, like an inkjet printer's ink, is very precise and does not leak.

It is small, designed to be placed on any bar top, and requires no prior training for use. It costs €2,995 and has been well received by the public and businesses, especially in hotels and at conferences. The last place it was installed was in the Barça Cafe of Barcelona FC, where they use it to print the club's logo. It is also in other high-profile places such as chef Paco Ronchero's Michelin-starred Madrid Casino venue Rockaberri in San Sebastian and the Hard Rock Cafe in Los Cabos in Mexico. Unfortunately, since March 2020 almost all of our clients have been closed in pandemic lockdowns, which has severely affected business. But the demand will return as soon as the hospitality sector does.

How did you become involved with your region's NUTRI+ project to produce foodtech solutions for those suffering from dysphagia and unable to ingest food? Is it a big problem?

We realized from a catering firm customer supplying old people’s homes that there are some 10m people in Europe, mostly the elderly and hospital patients, who cannot chew food. These people have to consume purees and jellies because it is dangerous for them to try and eat solids. They could choke or suffocate and are thus condemned to having to eat the same things for the rest of their lives. These people start losing their appetite and stop eating. We were asked if we could invent something to improve their quality of life and encourage them to eat. We started investigating how to make purees seem more appealing by making them look like solid food and this is the basis of the NUTRI+ program we are involved with.

How do you make purees look like solid food?

It is what we call a mimetic 3D printed technology, whereby we can make different menus every day for people with dysphagia. Their perception of their food changes and it even boosts their happiness. We know this because we have already done pilots. Our first printed mimetic products were chicken and pea, which have the same taste and texture, as confirmed by a group of food experts at the National Center for Food Technology (CNTA) where we make the formulations for the purees.

When you squash the mimetic chicken with a spoon, you can see that it is still a puree that can easily be digested by dysphagia sufferers, but we also use real chicken to make the puree. The deciding factor for the foods we can reproduce is that they have to have a solid form when cooked. For example, spinach or a bowl of soup is difficult to replicate because there is no structure or geometry. However, it is possible to reproduce a steak, a potato or hake fillet.

The technology we are working on for our third product is the 3D printer for purees. It will print the food authentically with a solid exterior although it is actually made up of puree. We scan the food and convert it into a data-based construct that can be replicated and rebuilt in 3D using the printer's molds. It works by first putting the puree in the device, where it’s pushed to an area where different molds create a realistic shape. Our device generates molds to make the form of chicken, steak or hake fillet. When the puree comes out of the mold, an inkjet head applies bio-ink to give it texture and color, giving the food a photorealistic texture. Like LASERGLOW, this product will not have a nozzle to create the designs as this is too slow and would not allow industrial scaling, which is essential for the product to complete its function.

We hope to commercialize the printer by the end of the year. The planned business model is to build the machines, sell them and charge royalties for printing to the companies who provide catering to residential care and also to food producers who could also retail them.

Your last major focus now is cell-based meat? Why is this so important to Cocuus?

This is actually our main focus because there are currently no scalable solutions for cell-based meat and we see that as essential. Because of the forums in which we participate, we believe that in 25–30 years it will be completely unsustainable to maintain a cow just to produce 200kg of meat after five years. In the same space, you can grow 6,000 tons of melons so that land used for agriculture is much more productively used than for rearing meat. In 2050, there will be 10bn people and 70% more demand for protein. We think cell-based meat will be the only way to eat meat if you don't live near a farm or are rich.

This is besides all the other concerns such as pollution from methane and animal suffering, which people are becoming increasingly aware of. Using cell-based meat eliminates all environmental contamination and, of course, the need for animals to be killed and endure awful living conditions. We also believe that a certain percentage of the population will always want to consume meat and not just plant-based products, which also impacts the environment.

The most advanced players in the meat industry are already positioning for cell-based technology and we aim to work with them to make it happen using the knowledge we have acquired in food printing.

Does Cocuus have a scalable method for cell-based meat production and what are your plans in this area?

We are working on various options in the cell-based area, which are all solutions to permit the scaling of cell-based food, but we are not creating the in-vitro cells ourselves. There are only seven or eight companies worldwide working with cells from meat, fish and fat in-vitro in bioreactors. Until now, cells grown in this way are like mush, lacking shape, and they need technology to form one. Other companies can now make burgers from a type of gellant and by applying the cultured cells, but we want to make fillets and structured meat.

So we have been researching how to print in 3D the extra-cellular structures that cells have in nature. Cells in a muscle don't grow in a bioreactor but in a 3D structure in the muscle itself, normally comprising collagen or hyaluronic acid. With our biotech team, we have discovered how to print the 3D structure in collagen and hyaluronic acid so that the stem cells feel more comfortable to reproduce in their natural habitat and will do so exponentially. Until now, there has been no process for the large-scale production of in-vitro cells of meat and fish so ours offers the first scalable solution and is also valid for plant cells.

Besides boosting the production of the cells themselves, you have further cell-based innovation applying math.

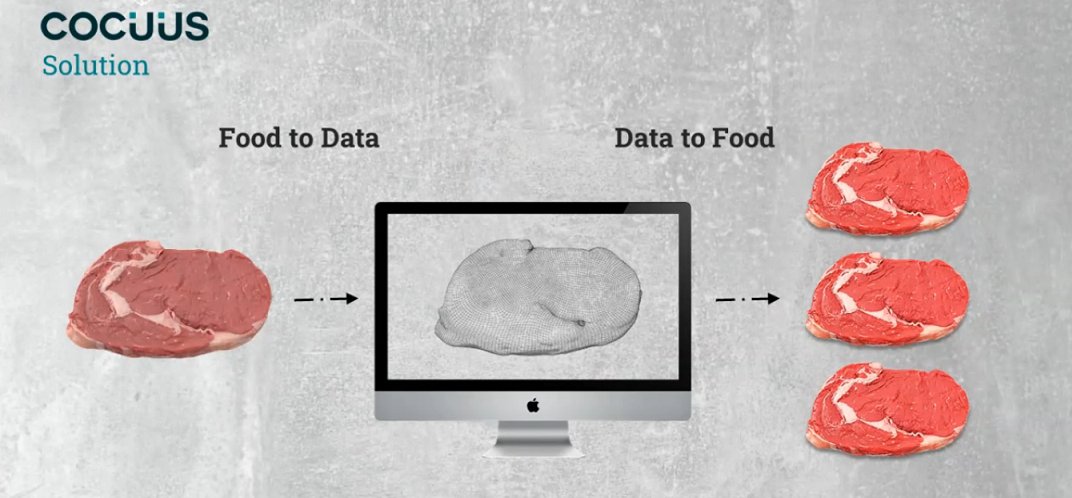

Yes. Basically, we say that we are converting food into data and then data back into food using alternative raw materials that can be meat, fish or plant-based cells. In order to make realistic, mimetic cell-based food such as a steak, we need to use math, just as we are doing with the food for those with dysphagia. Or we can only make burgers like others. So we make a CT scan of a joint of meat to discover its internal structure using the computer. The scan extracts all the data inside the meat, including percentages of fat, bone, meat and muscle, and also its geometry, and plots them in 3D.

We are converting food into data and then data back into food using alternative raw materials

We can then analyze any single part to convert it into separate 3D objects. So we can extract just the fat and, once separated, we can just print the fat. Because, in most cases, we will want to reproduce meat exactly how it is in terms of make-up, we also need the fat. So, for this reason, we have to recreate all the parts of the joint of meat separately and then put them together as they cannot be created together.

There must surely be interest in creating low-fat meat.

Yes, and when we perform the CT scan, we can then also optimize the data, for example by reducing the fat and increasing the meat content. This process gives us complete control over the product. We even use vegetable fat or another non-animal-based product for those not wanting to consume animals. We can even introduce, say, vitamin B12 in food for older people to cover dietary deficiencies.

Another thing you can do with this reconstruction method is to convert low-grade meat into a higher grade, more attractive product. So we can recreate a steak from cheaper cuts of meat and then prepare it in a high-grade way to increase the opportunity of the poor to be able to afford a steak in the future.

Besides steak, in terms of other completely mimetic food, we are also working with fish and have opted to reproduce salmon because of its morphology, characterized by its layers of fat and how its muscles are arranged. It is simpler to reproduce than other products.

These are the first steps in scaling the production of cell-based food. Do you have any hardware planned to contribute to this?

Our third cell-based industrialization technology is the first industrial hardware solution for processing cell-based food. This is a 3D printer for cell-based food with 300 extruders that prints the cells and extrudes them in the required quantities of meat and fat in order to make a steak. Bio-ink is added to the cells for the right color. The extruded fat and meat then gel together to form a steak using formulas we developed in the lab replicating nature and using collagen. We are now at the point of investigating how to get a realistic texture. The device will also work for salmon and hake. We are at the prototype stage and we aim to pilot at the beginning of next year with commercialization sometime in 2023. For our other technologies, we are looking at licensing them.