Natural Machines, the startup behind Foodini, the 3D food printer used by restaurants and food manufacturers, is preparing to list on the public stock exchange. It is one of 11 Spanish startups shortlisted to join TechShare, the pre-IPO educational training program by Euronext, Europe’s largest stock exchange, to help young companies familiarize themselves with the listing process and requirements.

Seeing the growing popularity of fresh food ingredients and personalized meals, two friends, Emilio Sepulveda and Lynette Kucsma, founded 3D food printing startup Natural Machines in 2012, inspired by vegan sweets produced at a friend’s shop. In 2014, they launched their 3D food printer prototype, Foodini, which has since been on the market with CE and FCC certifications, and backed with seven patents filed.

Today, Natural Machines has over 300 business clients around the world – including F&B players like the Melia and Marriott hotel groups, and food manufacturers such as Nestle, Arla and Mars Inc – and offices in Barcelona, New York, Milan and Beijing. Backed with funding of nearly $4.5m to date and with over $1m in revenue, Natural Machines is preparing to launch its latest product Foodini-Pro, which can simultaneously 3D print and cook food.

The difference lies in the laser technology integrated in the smart machine, with AI and infrared vision also used to control each cooking phase. Foodini-Pro "can cook food, like a burger or salmon filet, all the way through,” the company said. Overall, the printing and cooking process is more efficient and sustainable, using 90% less energy than traditional ovens, as the areas to be cooked are targeted.

First launched in 2015, TechShare’s latest January–June 2021 training program involves 119 tech companies from across Europe. Other Spanish participants in the current edition include new materials startup Nanoker Research, hyperloop transport developer Zeleros and fintech NoviCap. So far 22 Spanish companies have joined TechShare, which aims to prepare tech companies to list on the Euronext Growth market within the next one to three years.

Targets cost savings

The biggest costs for food producers lie in manufacturing and distribution, which make up nearly 80% of total operational expenses. A mini industrial-grade kitchen appliance would only need training for the local staff making the products for sale at the outlets. Manufacturers are also constantly looking for smart eco-friendly cookers that will one day replace microwaves and Thermomix appliances.

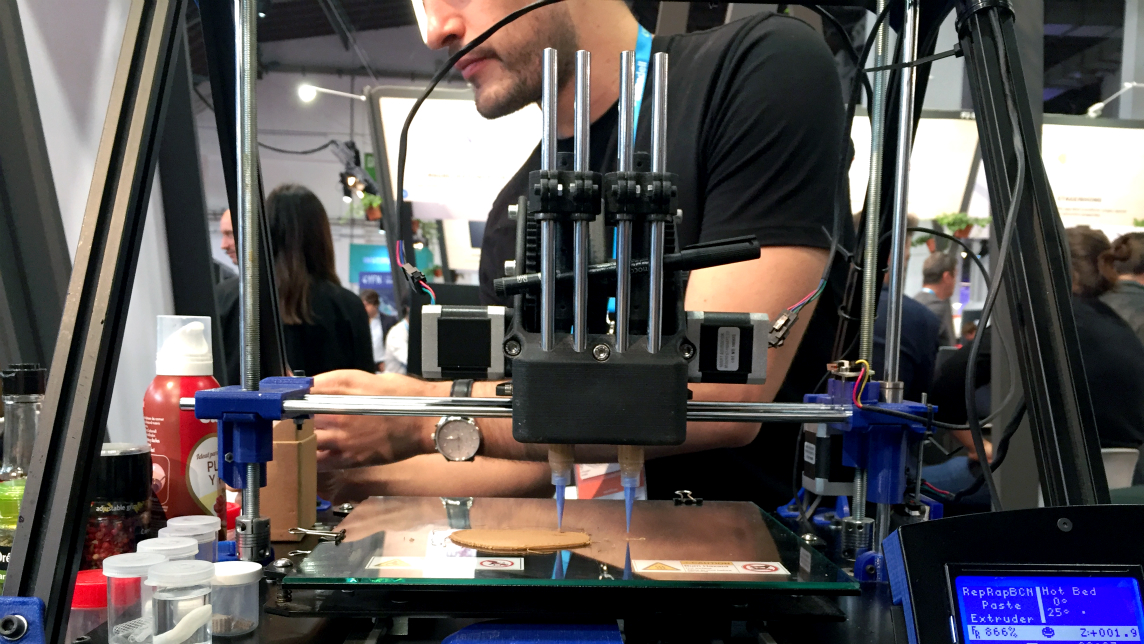

Foodini is an IoT device made of food-grade and food-safe materials. The appliance looks like a big microwave with a touch screen to manage the overall printing process. First, the recipe is selected on the screen and the ingredients needed are displayed. The user prepares the ingredients to fill in the five stainless steel capsules to be used for 3D food printing.

“If you want to make a snowflake-shaped pizza, for example, you just have to download an image from the internet. The rest is done by the machine,” Sepulveda said. Each capsule is heated to maintain proper food safety standards and prevent bacterial infections. It is also armed with a microchip to facilitate each capsule’s identification and correct positioning.

Using an extrusion-based technique, Foodini can print out nearly any type of food material and texture. The idea is to sell the machine with empty capsules to leave the user free to explore different mix of ingredients and healthier options. “There’s no one food regime that is right for every person, that’s why we don’t force people to buy pre-filled food capsules,” Kucsma said.

The food industry is becoming more competitive due to higher customer expectations. “We're already working on a new improved prototype," Sepulveda said at the 4YFN conference in 2016.

Long-term vision: the smart kitchen

Last year’s onset of the Covid-19 pandemic has delayed the commercialization of Foodini-Pro. The prototypes are currently manufactured in-house, with aims to complete the beta version and launch the first industrial design model to the market this year. In the second quarter of 2020, Natural Machines failed to raise enough money for its crowdfunding campaign to finance the marketing and sales of FoodinPro and had to delay the product launch.

“We believe that in 10 to 15 years, 3D food printers will become a common kitchen appliance in both home and professional kitchens, similar to how an oven or a microwave are common appliances in kitchens today,” according to the startup’s Wefunder pitch last year.

Natural Machines’ business development and sales strategy targets both B2B and B2C channels, with its main revenues coming from the sales of Foodini and its accessories. It also plans to earn from professional services like onboarding, customized print creation, training and on-site support. Another revenue stream will be from the provision of IoT data services.

The team is also identifying key markets of users that prioritize food innovation, sustainability, zero waste and better nutrition. Target markets continue to be Europe, North America and Asia-Pacific, as well as the UAE. Besides upmarket restaurants, food retailers and food manufacturers, new potential clients could also come from sectors like healthcare and nutrition companies.

“We’re following a typical, let’s say, kitchen appliance marketing strategy – commercial kitchens first and then consumers, as it happened with microwaves and food processors,” Kucsma said. “We have B2B clients lining up to be the first ones to try our device.” In fact, two Foodini machines have been bought by the celebrity Torres twin brothers and chefs behind the two Michelin-starred Cocina Hermanos Restaurant in Barcelona.

Apart from its R&D projects with healthcare company DomusVi and FMCG giant PepsiCo, Natural Machines is also looking to collaborate with real estate developers to introduce its devices in high-end apartments. “We have a long-term vision that extends beyond 3D food printing,” the co-founders said.

“Foodini uses many technologies that can be integrated into new kitchen solutions – 3D food printers are our first product line released."