Enzymes, which are proteins that catalyze chemical reactions, have been used in various industries for centuries, from tenderizing meat to making wine and cheese. But what if enzymes can be used for more than that, like in medicine or bioplastics? Singaporean startup Allozymes sees a huge market opportunity in making and improving enzymes, which can help industries such as F&B manufacturing, pharmaceuticals and cosmetics become more efficient.

Using technology developed at the National University of Singapore (NUS), Allozymes can produce enzymes faster and with fewer resources while maintaining accuracy, enabling manufacturers to use the enzymes to make raw materials, such as food coloring, flavoring and medicinal compounds at scale, without extracting those raw materials from natural sources.

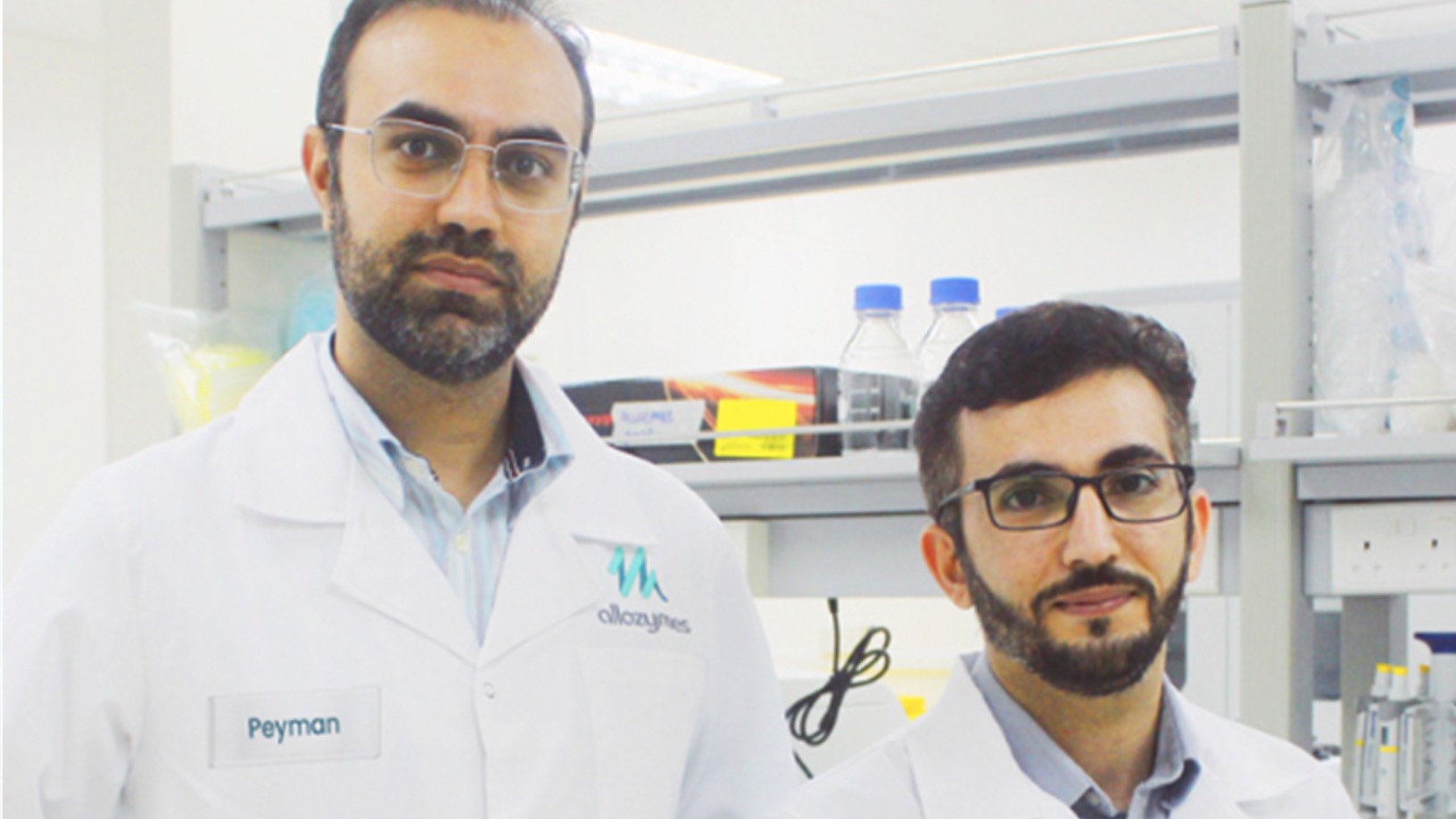

Peyman Salehian, CEO and co-founder of Allozymes, established the startup in 2019 with fellow NUS postgraduate researcher Akbar Vahidi, who was part of the university’s research team that developed enzyme engineering technology for the pharmaceutical industry. After obtaining the license to use the technology, Salehian and Vahidi raised $200,000 from SOSV and Entrepreneur First to optimize and improve the accuracy of the enzyme testing technology.

Salehian told CompassList recently that enzyme-driven manufacturing can replace not only natural extracts but potentially also petrochemicals. “We can find enzymes that can produce the same chemicals and engineer them to be stable in manufacturing conditions, for example, high temperatures or extreme pH,” he said. "Customers can get an effective enzyme in two to three months, rather than two years.”

In June this year, Allozymes was one of two startups that won $100,000 each at the Future Food Asia startup pitch competition. Salehian also told CompassList that Allozymes has just raised a $5m seed round led by Xora Innovation, a joint venture between Singapore sovereign fund Temasek and the country’s National Research Foundation, with participation from Entrepreneur First, TI Platform Management and SOSV’s incubator program HAX.

Just a drop

Enzyme engineering, whether to develop a new, novel enzyme or improve an existing one, begins by determining the enzyme’s protein sequence and the DNA sequence that a cell can use to produce that protein. The DNA sequence is used to produce millions of variants using a computer-assisted randomization procedure. This process simulates random mutations in nature over generations to help Allozymes find the enzyme with the desired properties in a much shorter timeframe.

Customers can get an effective enzyme in two to three months, rather than two years

Typically, to find the new enzyme candidates with the desired properties (e.g., temperature or pH tolerance), each sequence is synthesized and inserted into yeast or E. coli cells, which are left to multiply on a Petri dish. Each dish contains the chemicals with which the desired enzyme variant is expected to catalyze a reaction and is tested at the temperature or pH at which it is expected to work. If a reaction is detected, the cells are extracted from the dish to confirm the enzyme’s presence and sequence. Even with the help of robotics, the entire screening process can take a long time, given the large number of variants that need to be tested.

Allozymes cuts the time taken for the screening by replacing the Petri dish-scale testing with one that only requires droplets. Using microfluidic methods, Allozymes inserts the cells containing the variant into tiny droplets containing the target chemicals and testing environment. Each droplet, which has only one enzyme variant, becomes the testing platform, removing the need to wait for cells to multiply on a dish..

To improve the accuracy of the screening process, Allozymes does not use chemical tags, such as fluorescent groups, to detect the reaction.

“When you tag the compound that you want to find an enzyme for, it changes the chemical structure, and you might find an enzyme that reacts with this changed chemical instead,” Salehian said. Allozymes uses a combination of optics-based detection and other methods to verify a positive reaction. Salehian declined to mention the specifics.

Partnership, licensing models

Salehian said that Allozymes serves clients who want to improve an existing enzyme or clients who want to convert part of their manufacturing process to using industrial enzymes. For the former, the engagement is usually one-off, with Allozymes providing data on the improved enzyme for the client to use. For the latter, Allozymes pursues a longer-term partnership, where Allozymes would discover and develop the enzymes needed for the manufacturing process.

Salehian explained the business model with an example of a client that wanted to obtain a natural product through enzyme-based manufacturing. “Previously, the client had to buy 10 tons of tomato skin just to extract 3 kg of the compound they need,” he said. “We looked at the compound and determined the reaction pathway and the enzymes needed to produce that compound. We are now close to developing the enzymes that can produce that compound in a bioreactor without using a single tomato.”

The partnership model will be a stepping stone towards more lucrative business opportunities. “When you provide just the engineering service, clients pay a one-time fee. But if we have a licensing model, we have long-term revenue that consists of the licensing fee and royalty fees,” he added, noting that companies like Allozymes can even pursue an equity-based partnership with a share of the partner company in exchange for enzyme engineering services.

Salehian said Allozymes is still “pre-revenue,” as it is still in the early stages of its partnerships with clients. He added that his company has already signed MOUs worth more than $2m with some companies but declined to name them. He is confident that Allozymes will break even within the next two years.

“We are delivering on our projects much faster than expected, and with the evolving business model, we will be profitable.”

Billion-dollar market

Allozymes will use the seed funding to move to a bigger office and laboratory space, expand the team, and begin labeling the enzyme sequence database to enable machine learning. “In the future, customers may be able to explore the dataset and find the custom design enzymes that they need,” Salehian said.

Salehian is enthusiastic about the potential of enzyme-powered manufacturing. “Enzyme engineering services is worth $2.6bn globally, and it’s growing at a CAGR of 15%,” he said. “But when we are talking about replacing natural extracts with enzyme-catalyzed products made in bioreactors, we’re looking at a $43bn market.

"And then there’s a bigger market of green transformation, where we replace petrochemical derivatives with compounds made using enzymes; that’s worth $600bn.”

With that kind of potential in the market, Salehian expects Allozymes will face competition from companies outside of Asia-Pacific. However, these foreign competitors will have to carefully study their prospects and bear the high costs of setting up, giving Allozymes some breathing room.

“I think it will take them five years from now to expand into this region, and we have to use that time to establish ourselves in this region,” Salehian said.