Although more sustainability initiatives are being implemented in the textile industry, most are about new eco-friendly fibers and a lot of the sustainable benefits are lost due to the “dirty” processes in the rest of the value chain, according to Per Stenflo, co-founder of Swedish startup imogo.

“This is something that we want to address and have a solution for that,” Stenflo told CompassList in a recent interview. The solution is imogo’s proprietary dye-spraying technology which requires a liquor ratio of around 0.5–1 liter for 1 kg of fabric. The extremely low ratio enables manufacturers to substantially reduce the amount of treatment water and auxiliary chemicals used in the process, he said.

The new technology aims to disrupt conventional dyeing and finishing processes which are the most resource-consuming parts of the textile value chain, Stenflo said. It can potentially slash the amount of wastewater produced and the consumption of fresh water, energy and chemicals by up to 90% compared to conventional jet-dyeing systems.

About 20% of all industrial wastewater globally is generated from textile dyeing and finishing processes. “With our technology, we produce virtually no wastewater,” he added.

Manufacturers will have full control to precisely apply what’s required to the specific fabric by using the imogo system equipped with precision nozzles and a patented Pro Speed valve that helps to control the volume and consistency of the spraying process. The valve can also be used to boost the process to reach the highest-possible top speed.

About 20% of industrial wastewater is generated from textile dyeing and finishing processes

The innovative dyeing technology is the fruit of years of research by co-founder Ellinor Nitt, a researcher and lecturer at the Swedish School of Textiles. With almost 30 years of experience in textile dyeing and finishing, she had developed a new sustainable process for dyeing and finishing fabrics based on her research.

With Joacim Wellander joining as CEO, the co-founders established the Limhamn-based startup in 2018 to commercialize Nitt’s innovative processing solutions for industrial clients. The startup has won several awards including the Seal of Excellence by the European Commission for two years since 2019. It was also one of 15 finalists for the 2020 Global Change Award, selected from a total of 5,983 entries.

Industrial-scale installation

The Swedish startup has three main products for industrial applications on cellulosic fibers like cotton and hemp. “But we plan to expand the scope to include wool and polyester before the end of this year,” Stenflo said.

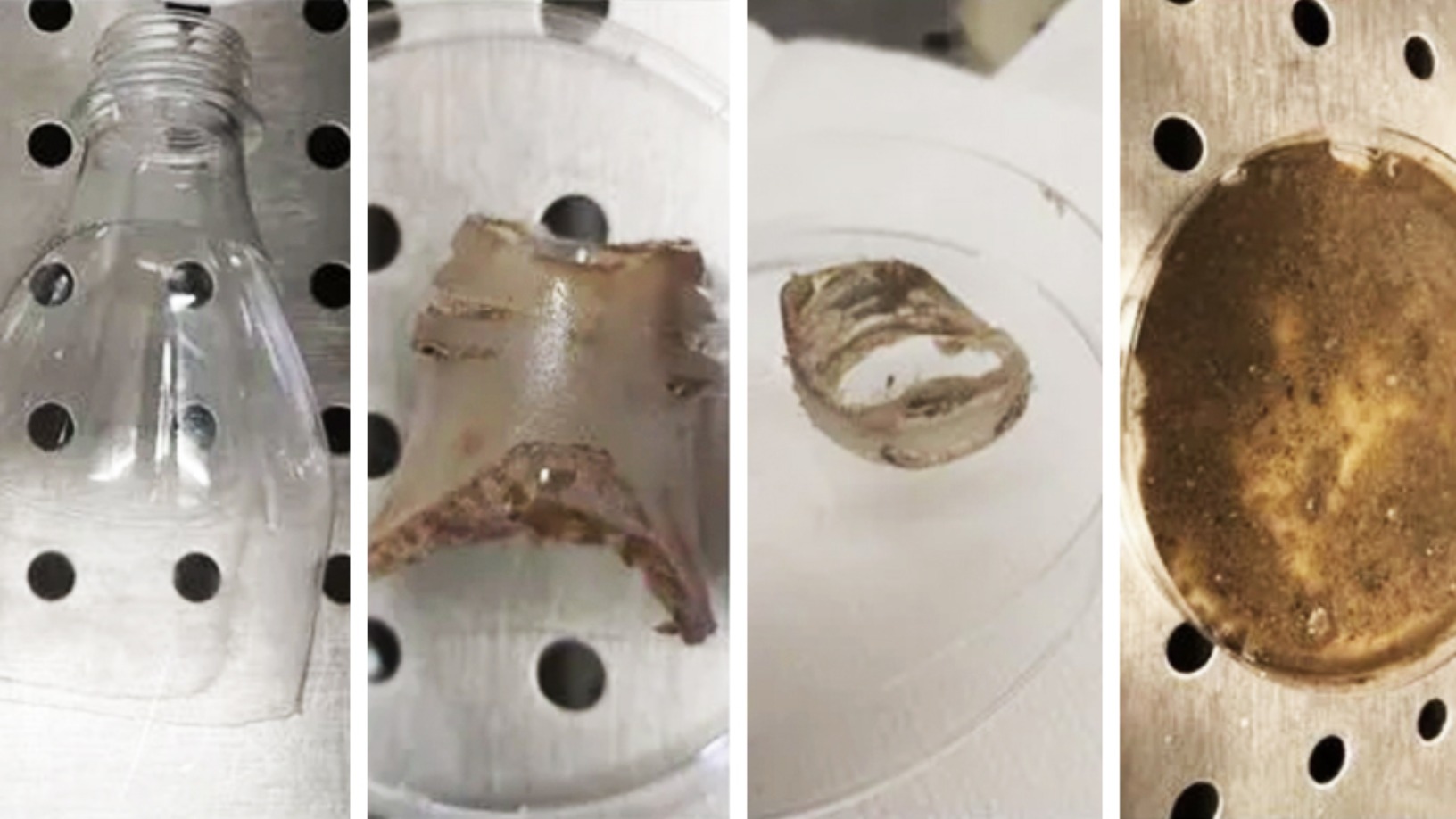

Dye-Max is a flexible high-speed spray application for dyeing and finishing processes. The FlexDyer system combines Dye-Max features with an autoclave fixation that uses a self-pressurizing process to fix the dye. F-Max is a scaled-down, cheaper version of Dye-Max specifically for use in the finishing process. The prototypes were launched in 2019.

There is also Mini-Max, a standalone laboratory unit that can be used with Dye-Max, FlexDyer and F-Max. The smaller lab unit is used to help clients avoid wasteful pre-runs by predetermining application volumes and conducting color-matching tests before starting the actual production. Clients can pre-set the desired specifications using the Mini-Max before transferring the parameters directly to the Dye-Max or F-Max database for full production.

Dye-Max will soon be used on an industrial scale for the first time by a local commission dyeing company 7H Färgeri. "The installation is already completed and the line is going to be in operation at the beginning of April after some software updates,” Stenflo said.

“It's an important step, given travel restrictions [amid Covid-19 pandemic]. The project will enable potential clients, especially international ones, to see how imogo's solution and its performance is validated,” he added

Although various companies from Asia have approached imogo for discussions, the startup will continue to focus on markets in Europe and Turkey. “We want to have a couple more installations in Europe and Turkey, before we feel confident to go to the other side of the world around Christmas,” he added. In Asia, the companies interested in Dye-Max are mainly from China, Sri Lanka, Vietnam, Pakistan and Bangladesh.

Good business sense

Being environmentally friendly is not the only factor that attracts potential clients, according to Stenflo who is responsible for the startup’s sales and finance. “It’s important, but not strong enough to appeal to businesses,” he said. “We have to make good business sense as well.”

Dye-Max can function as a standalone system, or it can also be integrated with an existing line by just replacing a padder – rollers for color application over fabrics The installation can mostly be done by the client. "We would have to be there for the startup that includes starting the machine and setting up parameters for specific customers as well as operator training, a relatively straightforward process that can be done in five days on site.”

A client’s upfront investment for Dye-Max is around the price of a traditional European high-end padder. According to Stenflo, new dyes or chemicals will not be required to use the system. Besides savings from using less water, energy, dye and auxiliary chemicals, imogo’s solutions can also help reduce labor costs. “The operation, which is completely digital, is a one-man job and simple to learn,” Stenflo said. “Quick changeovers of spray cassettes also mean that fewer people are required for the maintenance.”

According to Stenflo, right-first-time dyeing has always been a big issue. With traditional dyeing methods, 40–50% of all dye batches usually come out in the wrong shade and require toning, the process of re-dyeing to the right shade. “That requires a lot of additional time and resources.” The problem, he said, can be solved by using Mini-Max or Dye-Max because, unlike conventional dyeing methods, Dye-Max can be adapted to run optimized small batches at existing or higher productivity levels.

Government grants

Before the installation at 7H Färgeri, imogo had run pilot trials with various textile companies. “We had very positive feedback on the system,” Stenflo said. “There is an openness to change their existing technology and invest in Dye-Max.”

Stenflo also pointed out that going sustainable is something that has to happen in the industry. “We see dyehouses closing down or restricting production in many countries due to lack of water or pollution issues, as the traditional machinery requires a high volume of water,” he added.

The government has to take the lead in terms of governance and sustainability education, he added. Meanwhile, imogo has managed to garner some support from the government, including grants from governmental organizations.

Other companies are also emerging in the market, using different technologies for more sustainable dyeing and finishing processes. "We are happy to see them popping up and stand right behind them cheering for every success they have achieved,” said Stenflo. “We don't see them as competitors, but partners who help open the minds and the market for new, sustainable technologies.”

“It's a collective effort [needed] here to change the mentality, and open the market for new sustainable textile processing.”