Chinese biotech startup Bluepha has announced a $30m Series B funding round led by Lightspeed China Partners and GL Ventures. New investors Septwolves Venture Capital and Trinity Innovation Fund as well as existing investors Frees Fund, Qianhai FOF, Qihang Industrial Investment Fund and Frontier Enterprise Investment Fund joined the latest round.

The funding, the largest to be raised in a single round by a Chinese startup in the field of synthetic biology (SynBio), will mostly be used to build a factory that is expected to produce 10,000 tons of fully biodegradable polyhydroxyalkanoate (PHA) plastic a year when it is completed by end-2021 or mid-2022.

Only about 50,000 tons of PHA are manufactured annually worldwide compared to the 300m tons of plastic waste being generated every year, of which only 9% are recycled. Over half of the conventional plastics produced are for single-use and end up in the natural environment or landfills.

Bluepha President and co-founder Li Teng told CompassList in an interview that the company has cut its cost of PHA production by half from the current industry average but acknowledged that it is still more than how much it costs to produce conventional plastics.

But Li is confident that it is possible to achieve price parity with conventional plastics. "It will depend on the technology used to produce the biodegradable materials, scale of production and the price of petroleum,” said Li, who has a PhD in microbiology from Tsinghua University.

PHA plastic can biodegrade in soil or seawater within 3–6 months, but costs 3–10 times more to make than conventional plastics. The cost of PHA production has been estimated to be about $4,000 per ton. It is rare in China because of its higher cost compared to other bioplastics like PTA and PLA, but the latter two are, according to Li, biodegradable only under specific conditions of industrial composting.

"We already have renewables to replace fossil fuels, but there is not an obvious solution to the plastics problem,” Li said.

Lab to factory

Bluepha started as a university project on PHA production that Li participated in while pursuing his doctorate degree under the supervision of Chen Guoqiang, a world-renowned expert on PHA bioplastic and a professor at the School of Life Sciences at Tsinghua University. The project won Tsinghua University’s President’s Cup in 2015. The team also received financial support from the university’s incubator program X-lab.

In October 2016, Li co-founded Bluepha for the industrial production of PHAs with Zhang Haoqian, another scientist with a PhD in systems and synthetic biology from Peking University. The startup completed an eight-month pilot for its first-generation microorganism strain in Shandong province at the end of 2017.

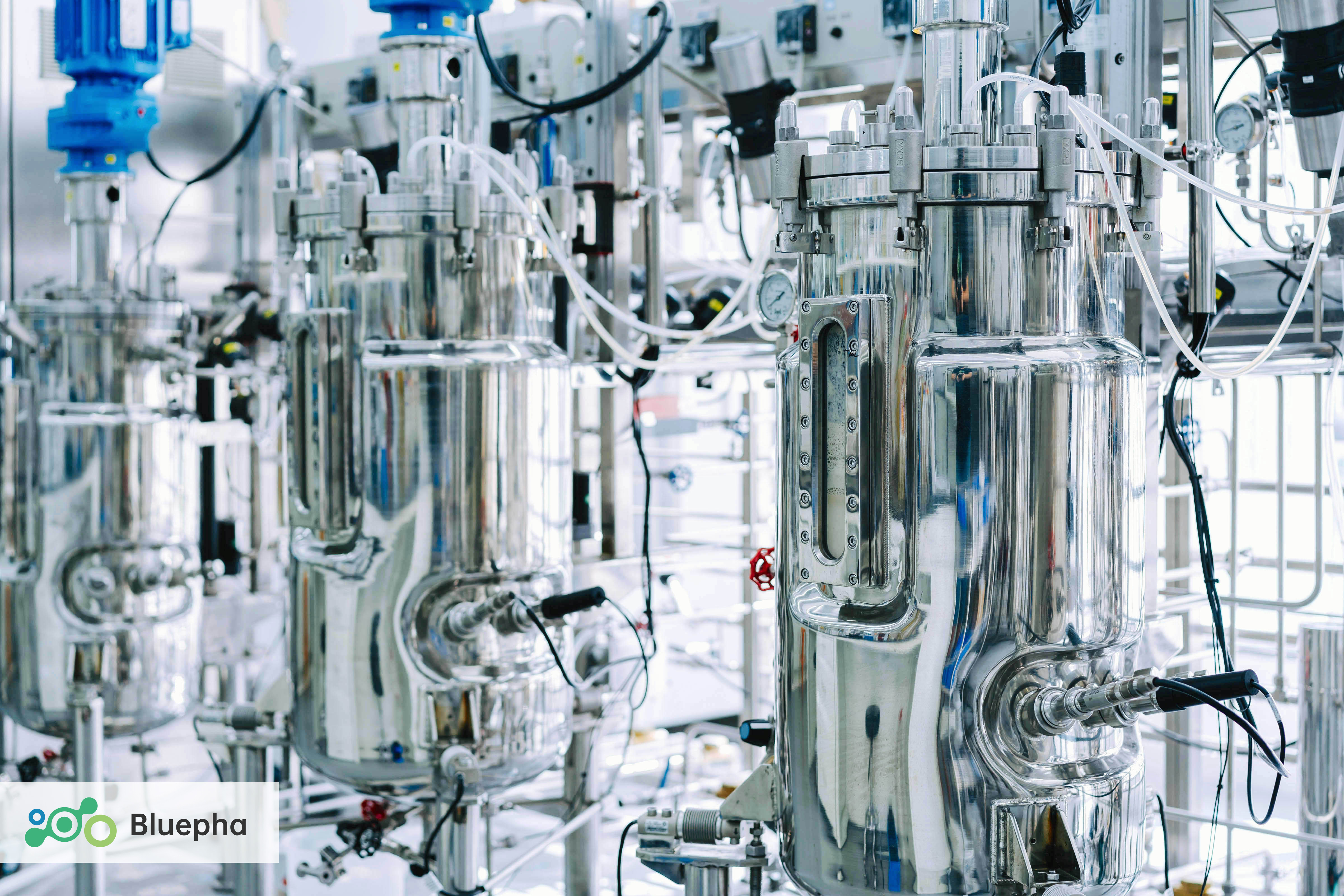

Commercial production began in 2018 using proprietary SynBio technologies designed to speed up microbe reproduction and boost the efficiency of PHA extraction and purification. This enabled Bluepha to produce a steady supply of high-performance PHA plastic.

Since it started PHA production, Bluepha has earned 8-digit RMB revenue every year with annual growth rates of 30%. According to Li, the company has received letters of intent for orders from around 30 clients, but is currently unable to fulfill all the orders due to limited production capacity.

Before the latest Series B funding, Bluepha had clinched four funding rounds from Leaguer Venture Capital, Frees Fund, TusPark Ventures and Green Pine Capital Partners. The company won the Future Planet Award for Sustainable Growth in 2017 and, in October 2020, was a finalist for the DBS Foundation Social Impact Prize.

Currently, Bluepha manufactures PHA powder or particles for use as raw materials by FMCG and F&B companies. “We will focus on this and leave developing products for specific applications to downstream companies,” Li said.

Building SynBio communities

It was by chance that co-founders Li and Zhang met in 2010 at the International Genetically Engineered Machine (iGEM) Giant Jamboree, a synthetic biology competition, where they were leading teams from their respective universities. Both teams won gold medals and they have remained close friends. Besides Li and Zhang, there are other iGEM winners on Bluepha’s team. R&D staff account for half of its 100 employees.

In 2017, several local universities and high schools approached Bluepha for help to prepare their students for the annual iGEM competition. “We are very familiar with the competition and of great influence in this field,” Li said. "We can help to build a synthetic biology community which is still in a nascent stage in China.”

The company now has a STEM education spin-off called Bluepha Lab, which also provides customized courses and lab services as well as other education products, such as short-term study tours. “We bring the students to an environment with a high level of biodiversity where they can take some samples for analysis to discover new microorganisms or do gene sequencing.”

Besides monetizing Bluepha’s R&D capability, Bluepha Lab has increased public awareness of synthetic biology. “Most of the students we have come from international schools and many of their parents are influential figures from all walks of life, [including] the capital market,” Li said. “It’s important for us," he added.

Bluepha has remained focused on being an R&D engine for biomanufacturing. The company is building a SynBio R&D automation platform called Holog to speed up the design and testing of microbes and develop novel bio-based molecules and materials for use in more applications in pharmacy, environment protection and food tech.

“We aim to help replace fossil carbon, including plastics, fuels, textiles and chemicals with biocarbon,” Li said. “It’s important to facilitate the transformation, especially in China, which is the world’s biggest manufacturer and where we can make a difference for the whole world.”